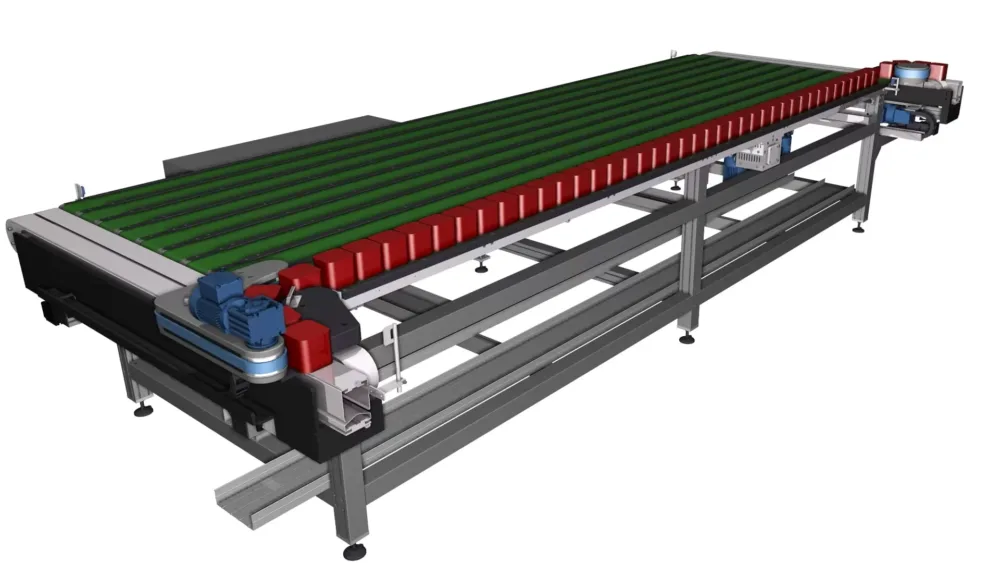

With in-line accumulation, the transport length of the production process is being used as buffer capacity. Speed differenences creates spacing between products, which is basically the buffering capacity of the system.

The in-line accumulator can also bridge vertical distances, which increases the buffer capacity. An optimal use of your floorspace. The in-line accumulation system can be integrated into your production line in the same simple way as a normal chain conveyor.

Features

- Available in FlexLink ® and MS Plus Automation ® version.

- Guaranteed First-in-First-out (FiFo) buffering.

- Controlled buffering through stoppers.

- Optimum use of floor space by vertical transport.